With more than 30 years of experience, Thermotech is a reputed company dealing with the design and manufacturing of the equipment for the process industry.

Thermotech has been a pioneer in Design, Manufacturing and Supply for over 30 years in the process industry. We manufacture cGMP and chemical reactors, Agitators, heat exchangers, pressure vessels, Mixing tanks, and process skids for speciality chemicals, pharmaceuticals, food/beverages, personal care, paints, petrochemicals, oil & gas, and other process industries.

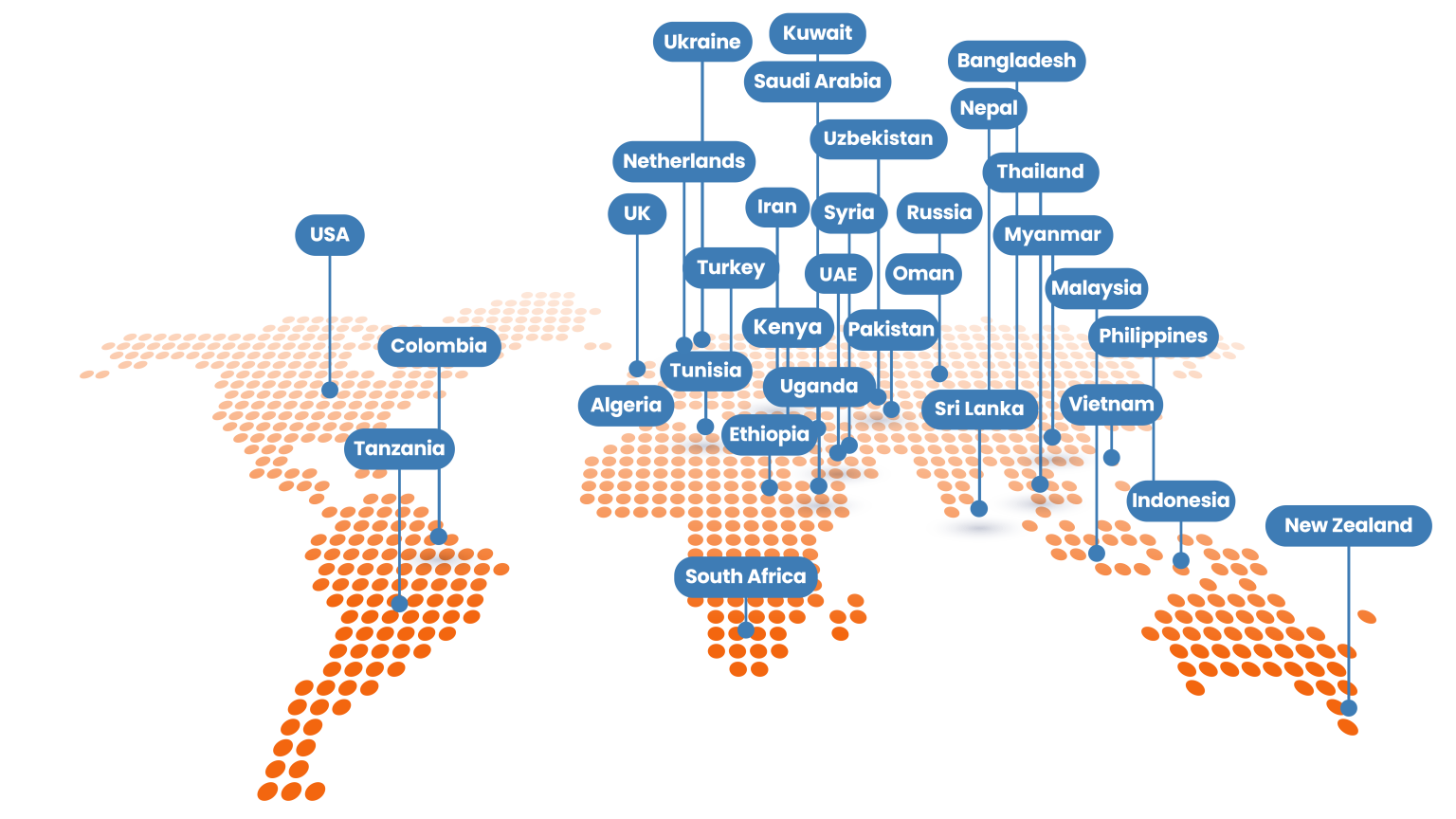

With more than 16,000 agitators installed all over the world, we have a strong database to handle all kinds of applications and an experienced technocrat team with the expertise to design agitators for various applications in liquid-liquid, liquid-solid and liquid-gas mixing.

Thermotech Engineering and Services Pvt. Ltd. has received the esteemed “Manufacturer of the Year” award from the Ministry of MSME at Vigyan Bhawan in Delhi. This achievement inspires us for the journey ahead, as we continue to innovate and contribute to the industry.

Quality, Efficiency, Innovation, Teamwork & Collaboration, Integrity,Ethics & Customer Satisfaction

To set the gold standard in the design and manufacturing of process equipment.

To produce equipment and goods which excels in quality, ensures on-time delivery and ensures 100% customer satisfaction.

To hire, train, and retain the best employees, and provide them with the optimum environment for personal growth, and contribution to organizational growth.

Plant & Manufacturing:

Our manufacturing facilities are spread over an area of 82,000 sq. feet, with a factory area of 57,000 sq. feet.

Thermotech has three factory units with an area of 55000 sq. feet, 42,000 sq. feet 32,000 sq. feet each. Each factory has overhead cranes and trimix concrete flooring.

The first factory at MIDC, Chinchwad is an ultra-modern facility having an open yard area of 42,000 sq. feet, and a covered factory area of 32,000. The next one at Talawade has an open yard area of 40,000 sq. feet with a covered factory area of 25,000 sq. feet. The covered workshop areas have a roof height of 10 meters and EOT cranes of 15 Tonnes each.

The third at Thermax Chowk has a sprawling 55,000 sq. ft. open area and 38,000 sq. ft. covered shed area.

Engineering & Design:

Thermotech has 30 plus years of experience in designing agitators for various applications. Whether the material is complex, or a reaction critical, we have dealt with it in the past, and can bring our experience to your benefit.

Complex materials or Critical reactions, whatever the requirement, Thermotech’s 30 years of experience have allowed them to advance in designing agitators for a multitude of applications. We have mechanical engineering expertise for the design, independent design verification, analysis, re-rating, fitness for service assessments, and fabrication specifications of Reactors , Pressure vessels, Columns ,Heat Exchangers. High standards are maintained and supported by highly qualified and trained quality control departments.

We maintain high standards supported by trained quality control departments with mechanical engineering expertise in designing, independent design verification, analysis and re-rating, fitness testing and fabrication specifications of Reactors, Pressure Vessels, Columns, and Heat Exchangers.

Quality Control Systems

Thermotech and quality are synonymous. We minutely look at every small detail, at every stage of the manufacturing process, from material procurement to painting and dispatch. All the incoming material is first tested by PMI and then with required lab tests as per respective quality assurance plans. All shafts are ultrasonically tested as well. The best quality of filler wire is used to ensure strong and proper welds. Polishing and buffing are done by an automated column and boom machine using abrasive material free from iron content. Roughness is measured by a state-of-the-art Mitutoyo Ra Meter.

testimonials

India's sole distributor for steridose products