INFRASTRUCTURE

We manufacture cGMP and chemical reactors, Agitators, heat exchangers, pressure vessels, Mixing tanks, and process skids for the speciality chemicals, pharmaceutical, food/beverage, personal care, paints, petrochemical, oil & gas, and other process industries

Plant & Manufacturing:

High Definition CNC Plasma cutting machine (Messer + Kjellberg)

Powered by a Kjellberg source and integrated with a Messer gantry & controller, this machine can cut stainless steel up to 36mm thick. The superior finish, which is a result of using a mixed gas (with an automatic mixer), results in a clean cut which is free from oxide/ slag. This superior cut eliminates the need to grind the material post cutting. The ability to transfer identification marking to every piece that is cut, aids material traceability.

Edge beveling machine (Gullco)

Use of this edge beveling machine (Gullco make) eliminates the grinding required to prepare the edge ( V- preparation) prior to welding. The edge thus prepared is uniform in terms of angle of weld, root gap, and root face. Such a uniform weld joint lends itself to excellent weld quality.

High performance flexible shaft polishing machine (Suhner)

This high speed German polishing machine provides a uniform surface finish even in hard to reach areas. The overall finish of the job is highly enhanced, and meets the needs of our pharmaceutical and biotech plant owners.

Mechanized column and boom polishing machines

These machines for internal and external polishing of vessel shells and dished ends provide a uniform finish to the vessel

On Call Facilities

Besides the in house facilities, we have several associates which give us access to the following facilities-

Laser, and water-jet cutting

PTFE lining, and Hylar PVDF coating

Orbital welding

CNC drilling and jig boring

Electro polishing and glass beading

Engineering / Design

Agitator and Reactor Design

We have 30 years of experience in designing the mixers as per applications. Whether the material is complex, or a reaction critical, we have likely dealt with it in the past, and can bring our experience to your benefit.

Static Equipment design

We have mechanical engineering expertise for the design, independent design verification, analysis, re-rating, fitness for service assessments, and fabrication specifications of pressure vessels. High standards are maintained and supported by highly qualified and trained quality control departments.

Quality Control Systems:

Quality system and personnel

Thermotech has robust quality systems that ensure that the right material is used, and the right procedure is followed in the conversion of raw material to finished product. We have a dedicated Quality manager, and a team of 9 field engineers ensuring strict compliance with procedure, and adherence to QAP

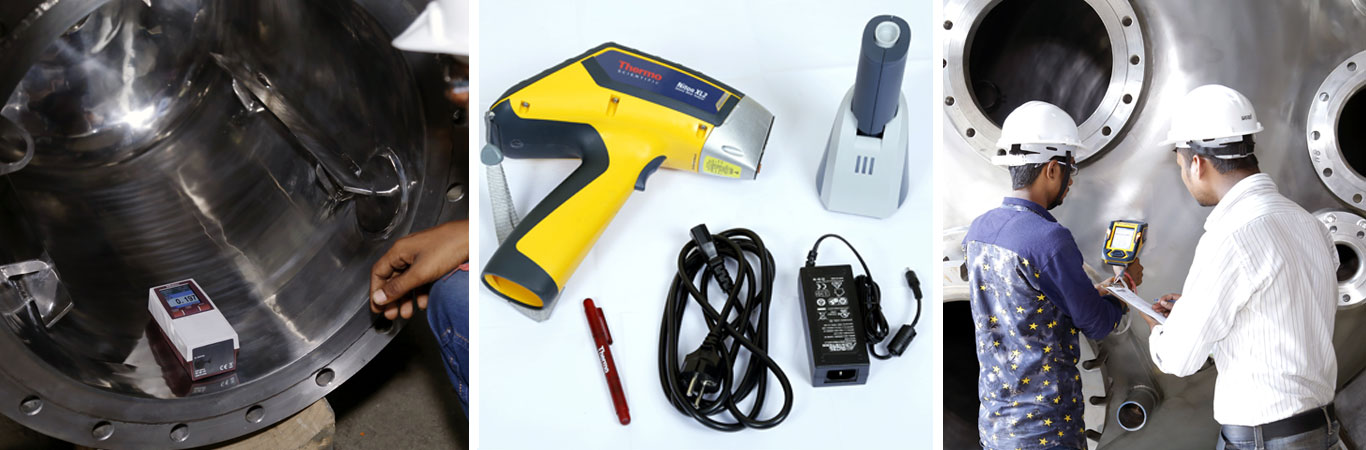

Thermotech and quality are synonymous. We take great care at every stage of the manufacturing process, from material procurement, till painting and dispatch. All the incoming material is first tested by PMI, all shafts are ultrasonically tested. The best quality of filler wire is used to ensure strong and proper welds. Polishing and buffing are done with abrasive media which are free from Iron content. Roughness is measured by state of the art Mitutoyo Ra Meter.

Material Traceability

Not only is all incoming material inspection and stamped, our CNC machine transfers the stamp to individual components while cutting. Our robust Quality control system thus ensures complete material traceability which is documented and provided as a dossier to clients.

WPS / PQR / WPQ & SOPs

We have in excess of 25 WPS/PQRs for a range of material, and thicknesses. All our welding personnel are qualified for the type of welding they perform. We also have welding experts who train and advise the personnel on best practices

We have well documented procedures for hydraulic testing, agitator assembly and testing. Our dedicated quality team ensures strict compliance to QAP and approved SOPs.

Fabrication Codes

Over our 30 year experience, we have manufactured as per various codes of construction, and complied with numerous standards. Some of them are-

ASME Sec. 8 Div 1

ASME Sec. 8 Div 2

MHLW (Ministry of Health, Labor, and Welfare) JAPAN

PED

DOSH (Malaysia)

BS 2790

PD 5500

API 650

TEMA R/ C/ B

Testing Facilities & instruments

Some notable features of the test facility include-

Provision to conduct hydrostatic testing for vessels with capacity up to 100,000 litres

A 150 HP power connection for load trials of agitators

A 100 HP Variable frequency drive (VFD)

Setup for Riboflavin testing

Apart from the usual instruments, our factory is equipped with the latest and best instruments, like-

PMI machine (Positive Material Identification) (brand- Niton)

Roughness measurement (brand- MituToyo)

Vibration/ RPM/ Temperature/ and thickness measurement